Shut-off dampers (AK 220)

- Made from sendzimir galvanised sheet steel or stainless steel

- Airtight according to DIN EN 1751 Class 4 for diameters 80 to 400

- Stop disc with age-resistant silicone gasket (EPDM optional)

- Laser-welded housing

- Push-fit ends with lip sealing system

- Push-fit ends airtight according to DIN EN 12237

- Housing leakage according to DIN EN 1751 Class C

- Optional with motor for electric or pneumatic adjustment

For shutting off air ducts

Tube body made of sendzimir galvanised sheet steel or optionally of stainless steel, “laser-welded” without intruding fold. The push-fit ends are press-calibrated according to DIN EN 12237, they are dimensionally stable and fit accurately.

In flow direction, the seal of the shut-off damper is airtight to a pressure of 1000 Pa, according to DIN EN 1751 Class 4 (certified by German Technical Inspection Authority - TÜV) for diameters 80 to 400 and up to 10m/s air velocity.

The shaft feed-through of the shut-off damper bearing is located in a maintenance-free and airtight screw connection.

Adjustment: The standard shut-off dampers are equipped with a manual adjustment device, which locks automatically (no tools required for adjustment and regulation). They can also be used for electric remote regulation.

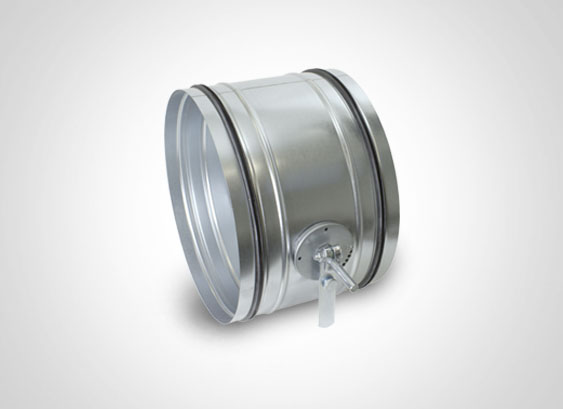

Insulation: Shut-off dampers with insulation are available in the insulation thickness 25 or 50 mm for all versions.

Temperature range: The shut-off dampers can be operated in temperature ranges between -15°C to +100 °C .

Installation information: According to DIN EN 12097, the duct system and the shut-off damper must be accessible for operation and maintenance.

Inflow velocity: up to 10m/s

Sealing system of the push-fit ends: The push-fit ends are airtight according to DIN EN 12237 Class D.

Robustness: In general the lip sealing is insensitive to damages in case of slightly canted or badly trimmed ducts.

Exchange: If the lip sealing is damaged or lost due to an unforeseen event, it is only necessary to put on a new loose sealing ring.

Removal: Because of the design of the sealing, the components can easily be separated from each other again.

Visible installation: Because no additional sealing components, e.g. tape, are required, the sealing design with lip sealing system is especially suitable for visible installation.

Hygiene: The smooth surface of the laser-welded housing prevents the accumulation of dirt and dust particles.

Stability: Non-ageing lip sealing made of EPDM - a material which is resistant to slightly aggressive vapours and chemical products.

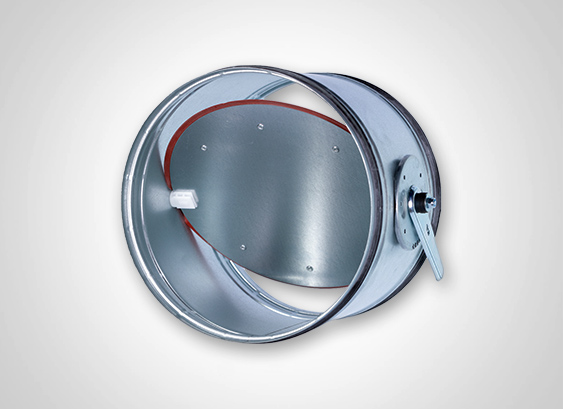

Version 1: Shut-off damper with manual adjustment AKH

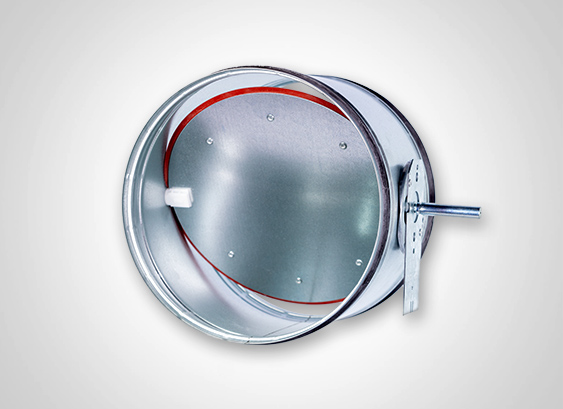

Version 2: Shut-off damper with console for electric adjustment AKM

Version 3: Shut-off damper with console for pneumatic adjustment (AKP)

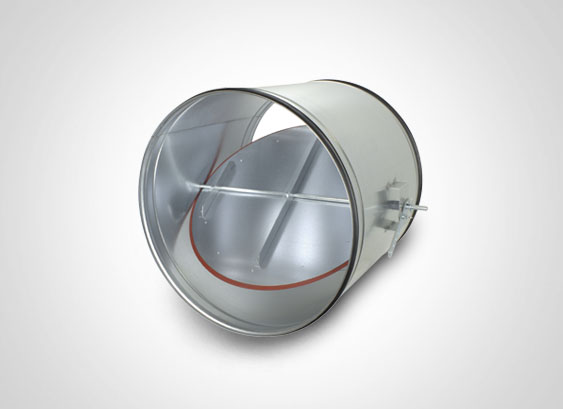

Version in stainless steel - INOX 316

Atex version

Ref. No.: 220

Other Languages

Shut-off damper - AKH, no. 220

Manufacturer: AEROTECHNIK E. Siegwart

Type: AKH, no. 220

Circular shut-off damper for shutting off the air ducts in a compact form with a housing made from galvanized steel – laser-welded, without overlapping; stop disc with age-resistant silicone gasket. Push-fit ends with lip sealing made from EPDM, shaft feedthrough of the stop disc is located maintenance-free and airtight, in flow direction airtight according to DIN EN 1751 class 4 up to a pressure of 1000 Pa for diameters 80 to 400, the push-fit ends with lip sealing airtight according to DIN EN 12237 class D, leakage of housing according to DIN EN 1751 class C.

Manual adjustment device

Range of temperature: -15°C to +100°C

Options:

- With mounted bracket for electronic or pneumatic actuator. (AKM, no. 220)

- ATEX execution according to Regulation 2014/34/EU

- Stainless steel INOX 316